-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

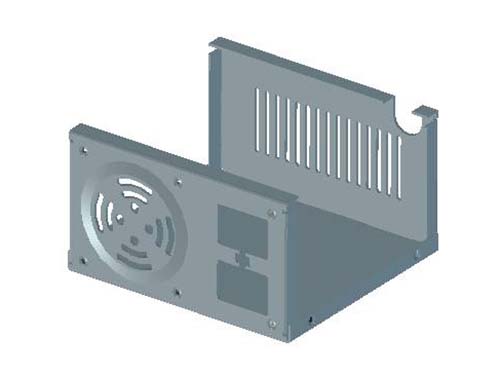

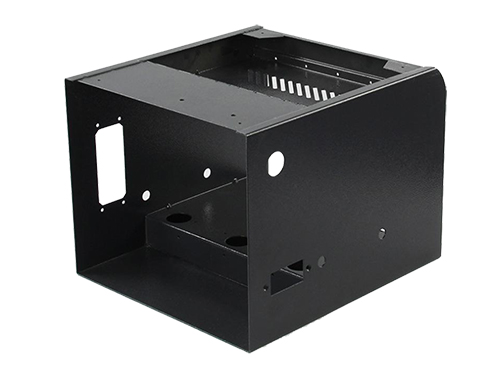

Sheet metal parts are essential structural and functional components fabricated from thin metal sheets(typically 0.05mm to 6mm thick)through a series of cold-working processes such as stamping,bending,cutting,and assembling.Characterized by high strength-to-weight ratio,cost-effectiveness,and design flexibility,these parts are ubiquitous in automotive,electronics,aerospace,construction,and consumer goods industries—serving as core building blocks for products ranging from simple brackets to complex equipment enclosures.

I.Core Definitions&Material Selection

1.What Are Sheet Metal Parts?

Sheet metal parts are formed from flat metal sheets or coils,maintaining the original material’s thickness(minimal thickness variation≤±0.1mm)through cold processing.Unlike cast or machined parts,they rely on plastic deformation and material separation to achieve desired shapes,ensuring structural integrity while minimizing material waste.Common forms include flat panels,bent brackets,hollow enclosures,and assembled structures with integrated features(holes,slots,flanges).

2.Common Materials for Sheet Metal Parts

Materials are selected based on application requirements such as strength,corrosion resistance,weight,and cost:

Ferrous Metals:

Carbon Steel(Q235,1018):Cost-effective,high ductility,suitable for general-purpose parts(brackets,chassis,hardware).

Stainless Steel(304,316):Corrosion-resistant,durable,ideal for food processing equipment,medical devices,and outdoor applications.

Galvanized/Galvannealed Steel:Zinc-coated for rust protection,used in automotive body parts,HVAC ducts,and construction components.

Non-Ferrous Metals:

Aluminum Alloys(5052,6061,3003):Lightweight(1/3 density of steel),corrosion-resistant,and excellent formability—suitable for electronics enclosures,aerospace parts,and automotive trim.

Copper/Brass:Superior electrical/thermal conductivity,used in electrical terminals,heat exchangers,and decorative components.

Magnesium Alloys:Ultra-lightweight,high strength,for high-performance applications(aerospace,premium electronics).

Special Materials:

Titanium Alloys:High strength-to-weight ratio,corrosion-resistant,for aerospace and medical devices.

Pre-painted Steel/Aluminum:Coated with decorative or protective layers,used in architectural cladding and appliance casings.

II.Key Manufacturing Processes for Sheet Metal Parts

Sheet metal parts are produced through a combination of cold-working processes,often integrated into automated production lines:

1.Cutting Processes(Material Separation)

Stamping/Blanking/Punching:As detailed in stamping processing,these processes cut or punch sheet metal into blanks or create holes/slots(refer to Stamping Processing Section II.1).

Laser Cutting:Uses high-power lasers for precision cutting of complex shapes(tolerance±0.02mm),ideal for low-to-medium volume production and custom parts.

Plasma Cutting:Suitable for thick sheet metal(6–20mm),offering fast cutting speeds for carbon steel and stainless steel.

Water Jet Cutting:Cold cutting method that preserves material properties,used for sensitive materials(aluminum alloys,titanium)and thick sheets.

2.Forming Processes(Material Deformation)

Bending:Forms angles(90°/180°),curves,or U/V-shapes using press brakes,with minimum bend radius dependent on material thickness(e.g.,0.5×thickness for aluminum,1×thickness for stainless steel).

Deep Drawing:Transforms flat sheets into hollow components(e.g.,enclosures,tanks)through stamping dies(refer to Stamping Processing Section II.2).

Roll Forming:Continuously bends sheet metal coils into long,uniform profiles(e.g.,roof panels,pipe supports)for high-volume production.

Embossing/Flanging:Adds reinforcing ribs,textures,or raised edges to enhance strength or assembly compatibility(refer to Stamping Processing Section II.2).

3.Assembly&Finishing Processes

Joining:Welding(MIG/TIG,spot welding),riveting,bolting,or adhesive bonding to assemble multiple sheet metal components.

Surface Finishing:

Protective coatings:Powder coating,electroplating(zinc/nickel),or painting to improve corrosion resistance and aesthetics.

Passivation:For stainless steel parts to enhance rust resistance.

Polishing/Brushing:For decorative finishes(e.g.,architectural trim,consumer electronics).

III.Core Characteristics&Advantages

High Strength-to-Weight Ratio:Cold working enhances material strength,making sheet metal parts lightweight yet durable—ideal for weight-sensitive applications(aerospace,automotive).

Cost-Effectiveness:High material utilization(85–90%),fast production cycles,and automated processing reduce unit costs,especially for high-volume orders.

Design Flexibility:Compatible with complex shapes,integrated features(holes,tabs,flanges),and custom profiles—supports rapid prototyping and design iterations.

Consistency&Precision:Dimensional tolerances range from±0.02mm to±0.1mm,with excellent repeatability across batches,ensuring assembly compatibility.

Recyclability:Most sheet metal materials(steel,aluminum,copper)are fully recyclable,aligning with sustainable manufacturing practices.

IV.Typical Industry Applications

Sheet metal parts are integral to diverse industries,with applications including:

Automotive:Body panels,chassis brackets,door frames,fuel tanks,and HVAC components—accounting for 30–40%of a vehicle’s weight.

Electronics&Electrical:Device enclosures(computers,smartphones),server racks,circuit board brackets,heat sinks,and electrical junction boxes.

Aerospace:Aircraft fuselage panels,wing ribs,engine mounts,and interior components(using lightweight aluminum/titanium alloys).

Construction:Roofing panels,wall cladding,ductwork,structural brackets,and scaffolding components.

Home Appliances:Refrigerator/freezer shells,washing machine drums,air conditioner housings,and kitchenware(stainless steel sinks,cookware).

Medical Devices:Surgical instrument housings,diagnostic equipment frames,and hospital bed components(stainless steel for sterility).