-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

Stamping parts are high-precision metal components produced through stamping—a cold-forming manufacturing process that shapes, cuts, or deforms metal sheets, coils, or strips using custom-engineered dies and presses. By applying controlled mechanical force at room temperature, stamping creates consistent, complex geometries with tight tolerances, making these parts indispensable across automotive, electronics, aerospace, construction, and consumer goods industries. Unlike machined parts that remove material or cast parts formed via molten metal, stamping relies on plastic deformation or shearing to retain material integrity, offering cost-effectiveness and efficiency for high-volume production.

I. Core Definitions & Classification

1. What Are Stamping Parts?

Stamping parts encompass a broad range of components fabricated through one or more stamping sub-processes, with key characteristics including:

Manufactured from thin to medium-thickness metal (0.05mm–6mm) such as steel, aluminum, or copper.

Dimensional tolerances ranging from ±0.01mm to ±0.1mm, ensuring high interchangeability.

Adaptable to simple (washers, clips) or complex (automotive body panels, electronic connectors) geometries.

Produced in high volumes (10k–10M+ units/year) with consistent quality via automated lines.

2. Key Classification of Stamping Parts

Stamping parts are categorized by processing method and functionality, reflecting the versatility of stamping technology:

By Processing Type:

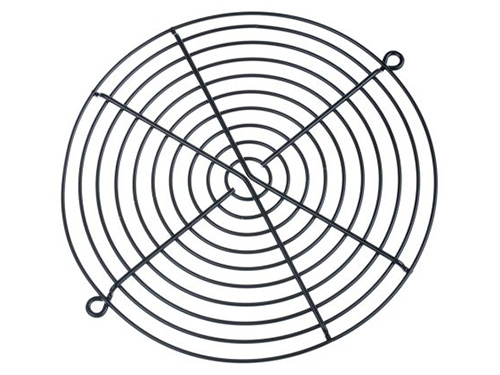

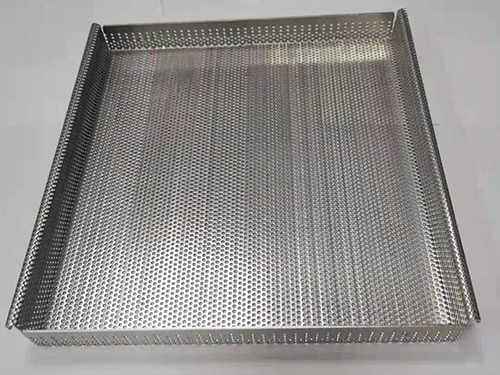

Cutting Stamping Parts: Formed via material separation (blanking, punching, trimming)—e.g., washers, gaskets, perforated sheets.

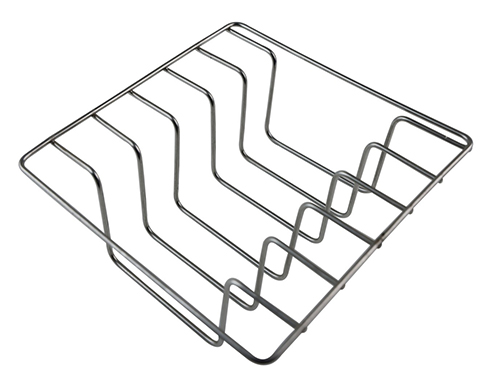

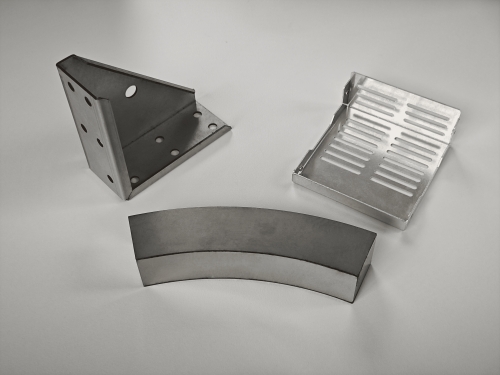

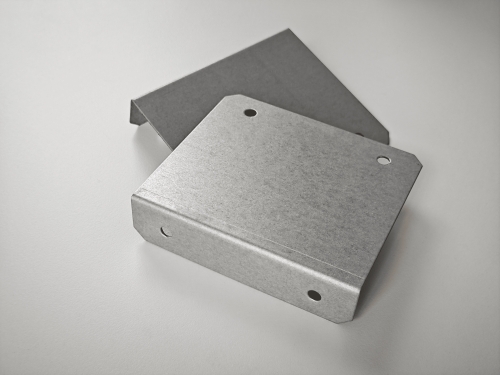

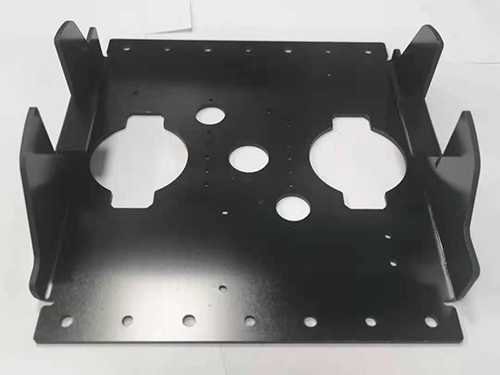

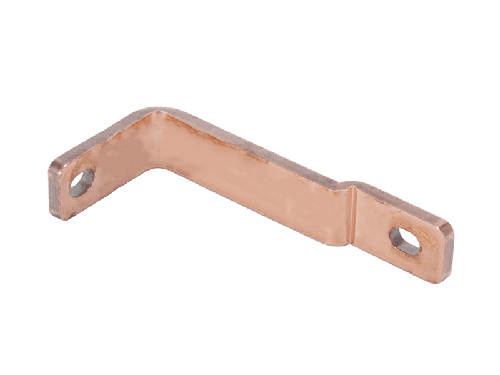

Forming Stamping Parts: Shaped via plastic deformation (bending, drawing, embossing)—e.g., brackets, housings, curved panels.

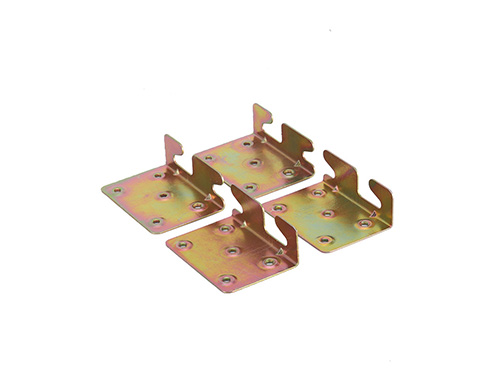

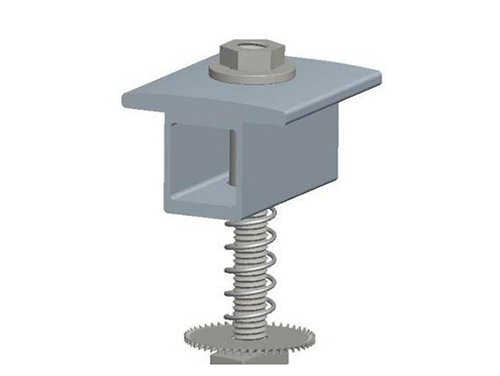

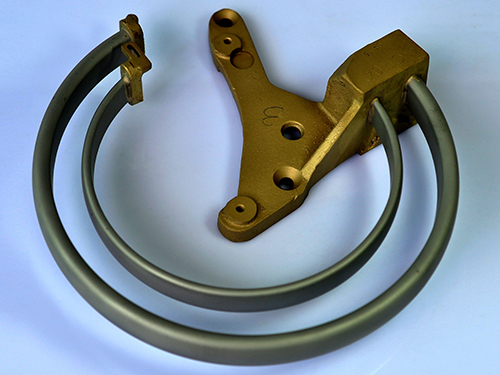

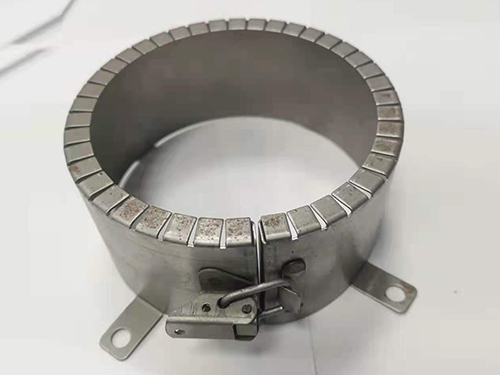

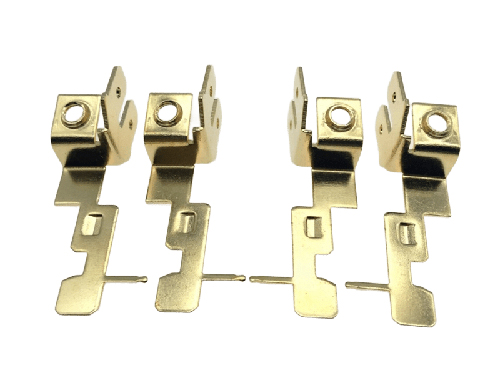

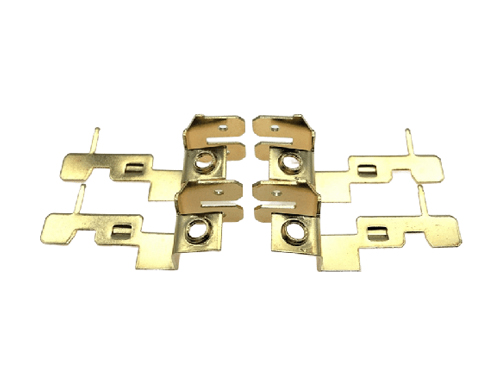

Composite Stamping Parts: Integrate multiple processes (punching + bending + forming)—e.g., automotive door hinges, electrical terminals.

By Material Type:

Ferrous Stamping Parts (carbon steel, stainless steel, galvanized steel)—for structural and high-strength applications.

Non-Ferrous Stamping Parts (aluminum, copper, brass)—for lightweight, conductive, or corrosion-resistant needs.

By Application Scale:

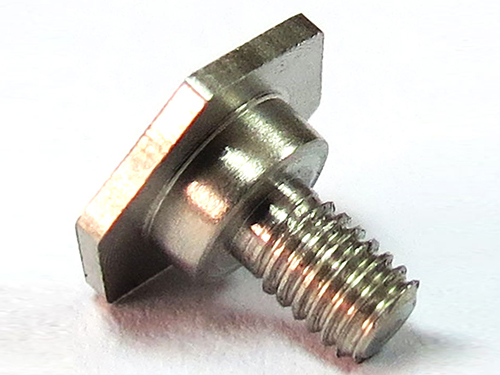

Miniature Stamping Parts (≤10mm): Electronic connectors, battery contacts, micro-fasteners.

Medium-Sized Stamping Parts (10mm–500mm): Brackets, chassis components, household hardware.

Large-Scale Stamping Parts (>500mm): Automotive body panels, construction cladding, industrial equipment frames.

II. Material Selection for Stamping Parts

Materials for stamping parts must balance ductility, strength, and formability to withstand cold-forming without failure. Common selections include:

Ferrous Metals:

Low Carbon Steel (1010, 1018, Q235): High ductility (elongation ≥20%), cost-effective—ideal for general-purpose parts (brackets, clips, washers).

Stainless Steel (304, 316): Corrosion-resistant, durable—used in food processing equipment, medical devices, and marine components.

Galvanized/Galvannealed Steel: Zinc-coated for rust protection—suitable for automotive parts, HVAC ducts, and outdoor hardware.

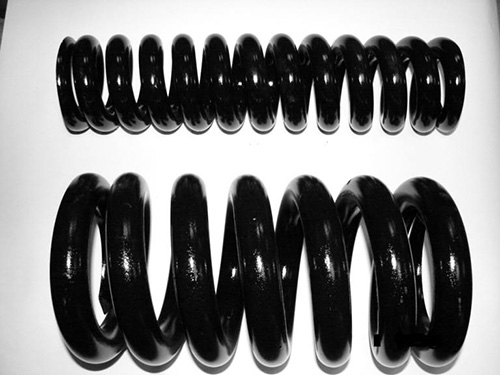

Spring Steel (65Mn, 55Si2Mn): High elasticity—for clips, springs, and retaining rings.

Non-Ferrous Metals:

Aluminum Alloys (5052, 6061, 3003): Lightweight (1/3 density of steel), excellent formability—for electronics enclosures, automotive trim, and aerospace parts.

Copper/Brass (C11000, C26000): Superior electrical/thermal conductivity—for connectors, terminals, and heat exchangers.

Magnesium Alloys: Ultra-lightweight, high strength—for high-performance applications (aerospace, premium electronics).

Material Thickness Range: 0.05mm–6mm (optimal: 0.1mm–3mm) for most stamping processes; specialized heavy-duty stamping handles up to 12mm thick materials.

III. Manufacturing Processes for Stamping Parts

Stamping parts are produced through combinations of core stamping processes, often integrated into automated production lines:

1. Core Stamping Processes

Cutting Processes: Blanking (cutting blanks), punching (creating holes/slots), trimming (refining edges), and piercing (precision hole-making)—for separating material into desired shapes.

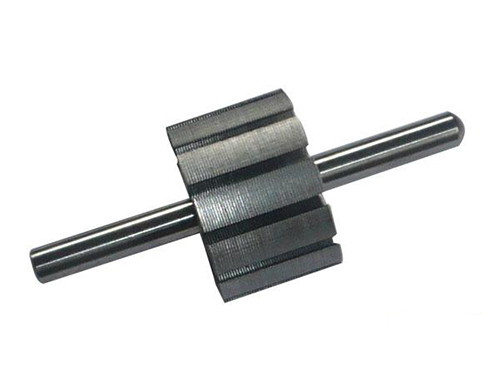

Forming Processes: Bending (angles/curves), drawing (hollow components), embossing (patterns/ribs), flanging (strengthening edges), and coining (fine details)—for shaping material without separation.

2. Production Modes

Progressive Die Stamping: Integrates multiple processes into one die set, with automated coil feeding—ideal for high-volume small parts (e.g., terminals, gaskets) with cycle speeds up to 1000 parts/minute.

Transfer Die Stamping: Uses robotic arms to move workpieces between dies—for large or complex parts (e.g., automotive chassis components) requiring multi-step forming.

Compound Die Stamping: Completes multiple processes (e.g., blanking + punching) in a single press stroke—for medium-volume parts needing high precision.

3. Secondary & Finishing Processes

Joining: Welding (spot welding, MIG/TIG), riveting, or adhesive bonding—for assembling multi-component stamping parts.

Surface Treatment: Electroplating (zinc, nickel), powder coating, painting, passivation (stainless steel), or polishing—enhances corrosion resistance, aesthetics, or conductivity.

Deburring: Removes sharp edges via mechanical or chemical methods—ensures safety and assembly compatibility.

IV. Core Advantages of Stamping Parts

High Precision & Consistency: Enabled by precision dies (CNC-machined + EDM) and automated presses, ensuring uniform dimensions across batches—critical for assembly line compatibility.

Cost-Effectiveness for High Volume: Fast production cycles (50–1000 parts/minute) and high material utilization (85–90%) reduce unit costs, outperforming machining or casting for large batches.

Superior Structural Strength: Cold forming refines metal grain structure, increasing tensile strength by 10–30% compared to raw materials—improves durability and load-bearing capacity.

Design Flexibility: Compatible with complex geometries, integrated features (holes, tabs, reinforcing ribs), and custom shapes—supports multi-functional part design and reduces assembly steps.

Efficiency & Automation: Easily integrated with robotic feeding, inspection, and packaging systems—minimizes labor costs and human error.

V. Typical Industry Applications

Stamping parts are ubiquitous across industries, serving as core components for countless products:

Automotive Industry: Body panels, brackets, hinges, door handles, engine fasteners, fuel tank components, and electrical connectors—accounting for 40–60% of automotive metal parts.

Electronics & Electrical: Connector terminals, battery contacts, circuit board brackets, heat sinks, smartphone middle frames, and power supply enclosures—requiring miniaturization and high precision.

Home Appliances: Refrigerator door hinges, washing machine balance weights, air conditioner compressor parts, kitchenware (stainless steel sinks, cutlery), and appliance casings.

Construction & Hardware: Door/window hinges, curtain wall brackets, pipe fasteners, scaffolding components, and roofing clips—needing corrosion resistance and load-bearing capacity.

Aerospace & Defense: Precision fasteners, instrument housings, aircraft structural brackets, and missile components—using high-strength alloys (titanium, stainless steel) for extreme environments.

Medical Devices: Surgical instrument components, implantable parts (titanium stents), and diagnostic equipment frames—requiring biocompatibility and strict precision.

Consumer Goods: Clips, buckles, jewelry findings, and decorative metal parts—balancing aesthetics and functionality.

VI. Quality Control & Industry Standards

1. Quality Assurance Measures

Dimensional Inspection: Coordinate Measuring Machines (CMM), optical comparators, digital calipers, and go/no-go gauges—verify critical dimensions, tolerances, and geometric accuracy.

Surface Quality Checks: Automated Optical Inspection (AOI) systems detect scratches, burrs, or deformations; roughness tests (Ra ≤0.8μm for decorative parts) ensure finish consistency.

Mechanical Testing: Tensile tests (ASTM E8), hardness tests (Rockwell/Brinell), and fatigue tests—confirm post-stamping material strength and durability.

Corrosion Resistance Testing: Salt spray tests (ASTM B117) for coated/stainless steel parts—typical pass criteria: 24–72 hours without rust (up to 1000 hours for marine applications).

Process Monitoring: Real-time tracking of press force, stroke speed, and die wear—prevents batch defects and ensures process stability.

2. Compliance Standards

International Quality Standards: ISO 9001 (general manufacturing), IATF 16949 (automotive), AS9100 (aerospace), and ISO 13485 (medical devices).

Material Standards: ASTM (USA), DIN (Germany), JIS (Japan), and GB (China)—for specifying material composition and performance.

Safety Standards: OSHA (USA), CE (EU), and GB 20905 (China)—for press operation and workplace safety.