-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

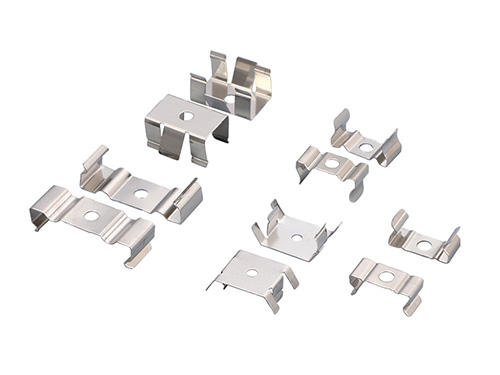

Hardware stamping parts are high-precision metal accessories manufactured through stamping processes,where metal materials undergo plastic deformation or separation under applied pressure.As widely used foundational components,they leverage advantages of high precision,efficiency,and cost-effectiveness to become indispensable in industries such as automotive,electronics,home appliances,and construction—spanning the entire industrial chain from daily necessities to high-end equipment.

I.Core Material Selection

Materials for hardware stamping parts must balance ductility,strength,and formability to meet performance requirements of diverse applications:

Carbon Steel:Mild steel grades like Q235 and 1018 offer low cost and excellent ductility,suitable for general-purpose parts such as brackets and fasteners;spring steel(65Mn)with superior elasticity is used for clips,shrapnel,and other parts requiring reset functionality.

Stainless Steel:304 stainless steel provides corrosion resistance and easy cleaning,ideal for kitchenware and medical devices;316 stainless steel with enhanced salt spray resistance is applied in marine equipment and chemical machinery.

Non-Ferrous Metals:Aluminum and its alloys(5052,6061)are lightweight with good thermal conductivity,used for electronic casings and automotive decorative parts;copper/brass,excellent in electrical and thermal conductivity,serve as core materials for electrical terminals and connectors.

Special Materials:Galvanized and tin-plated steel combine rust resistance and formability,suitable for home appliance casings and food packaging;titanium alloys and high-temperature alloys meet extreme environment requirements in aerospace and other high-end fields.

II.Key Processing Technologies

Hardware stamping achieves complex shapes through combined processes,with core techniques including:

Separation Processes:Blanking(cutting raw material into blanks),punching(creating holes/slots),and trimming(refining edges of formed parts)ensure basic dimensional accuracy.

Forming Processes:Bending(shaping angles/curves),deep drawing(manufacturing hollow parts like housings),flanging(strengthening edge strength),and embossing(adding patterns/logos)realize functional geometries.

Composite Processes:Progressive die stamping integrates multiple operations with automated feeding for mass production of small parts(e.g.,terminals,gaskets);transfer die stamping handles complex components with one-time forming to improve efficiency.

III.Core Advantages and Performance Features

High Precision&Consistency:Supported by precision molds and automated equipment,dimensional tolerances range from±0.01mm to±0.1mm,ensuring strong interchangeability of mass-produced parts for assembly accuracy.

High Efficiency&Cost-Effectiveness:Stamping speeds reach hundreds to thousands of parts per minute,with material utilization exceeding 85%,significantly reducing unit production costs for large-scale industrialization.

Superior Structural Strength:Cold working refines metal grain structure,increasing tensile strength by 10%-30%—resulting in better impact resistance and wear performance than cast or machined parts.

Diverse Morphologies:Capable of processing flat,curved,and hollow complex structures with both rigidity and toughness,integrating multi-functional features(e.g.,holes,buckles,reinforcing ribs)to reduce assembly steps.

IV.Typical Application Scenarios

Automotive Industry:Body brackets,engine fasteners,instrument panel frames,and door hinges—accounting for over 60%of automotive hardware components.

Electronics&Electrical:Mobile phone middle frames,battery shrapnel,connector terminals,and circuit board brackets,demanding miniaturization and high precision.

Home Appliances:Refrigerator door hinges,washing machine balance rings,air conditioner heat sinks,and kitchenware handle fasteners,balancing functionality and economy.

Construction Hardware:Door/window hinges,curtain wall hangers,pipeline fasteners,and guardrail connectors,requiring corrosion resistance and load-bearing capacity.

High-End Equipment:Aerospace fasteners,medical device accessories,and industrial instrument casings,with strict material and precision requirements.

V.Quality Control and Selection Criteria

Quality control focuses on three core aspects:Dimensional accuracy verified by CMM and optical measuring instruments;surface quality requiring no burrs/scratches,with corrosion resistance ensured by salt spray tests;mechanical properties validated through tensile and hardness tests.Selection considerations include:

Material matching with operating environments(e.g.,316 stainless steel for coastal areas)

Process adaptation to structural complexity(progressive dies for complex parts)

Tolerance alignment with assembly requirements(strict tolerances for precision components)

Preference for suppliers certified to ISO 9001/IATF 16949 for batch stability.

Hardware stamping parts serve as the cornerstone of industrial manufacturing with irreplaceable cost-performance and adaptability.As mold technology and automation advance,their precision and application scope will continue to expand,providing core support for lightweight and precision development across industries.