-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

Folding parts are specialized structural and functional components designed to enable battery systems to achieve foldability,compact storage,and adaptive deformation while maintaining electrical performance and structural integrity.Widely applied in flexible electronics,portable energy storage,foldable solar panels,and electric mobility devices,these parts integrate mechanical flexibility,electrical stability,and environmental sealing—addressing the core demands of miniaturization,portability,and space optimization in modern battery-powered products.This document comprehensively covers the classification,material selection,manufacturing processes,performance requirements,and industry applications of battery folding parts,incorporating the latest technical innovations and standard specifications.

I.Core Definitions&Functional Requirements

1.What Are Battery Folding Parts?

Battery folding parts refer to a category of components that realize reversible folding or bending functions in battery systems,including structural connectors,flexible encapsulation layers,deformable electrodes,and folding mechanisms.Their core functional roles include:

Mechanical Flexibility:Enable repeated folding(≥10,000 cycles)without structural fatigue or performance degradation,supporting folding angles from 0°to 180°(or even 360°for rollable designs).

Electrical Continuity:Maintain stable current transmission during folding/deformation,with contact resistance variation≤5%under maximum strain(50%stretch for flexible batteries).

Structural Protection:Protect internal cells/electrodes from mechanical stress,moisture,and external impacts,meeting sealing standards≥IP65 for portable devices.

Space Optimization:Reduce storage volume by 40–70%through folding design(e.g.,foldable solar panels with 3–5 folding sections).

Compatibility:Adapt to diverse battery types(soft-pack lithium-ion,flexible thin-film,solar cells)and application scenarios(wearables,electric folding bikes,portable chargers).

2.Key Performance Benchmarks

Folding parts must meet rigorous performance criteria to balance flexibility and reliability:

Folding Durability:≥10,000 folding cycles(180°repeated folding)with no cracks,delamination,or electrical failure.

Mechanical Strength:Tensile strength≥20MPa for flexible substrates;bending stiffness≤5N·m²/m to ensure foldability.

Electrical Stability:Conductivity≥100S/cm for flexible conductors;insulation resistance≥10¹²Ωfor encapsulation layers.

Environmental Adaptability:Operating temperature range-40℃to 85℃;resistance to humidity(85%RH,1000h)and UV radiation(≥1000h exposure).

Safety Compliance:Meet EN 62133(battery safety)and EN 61000-6-3(EMC)standards for portable devices;flame retardancy≥UL94 V-0.

II.Core Classification of Battery Folding Parts

Battery folding parts are categorized by function and application scenario,with distinct designs for flexible batteries,foldable energy storage systems,and electric mobility devices:

1.Structural Folding Mechanisms

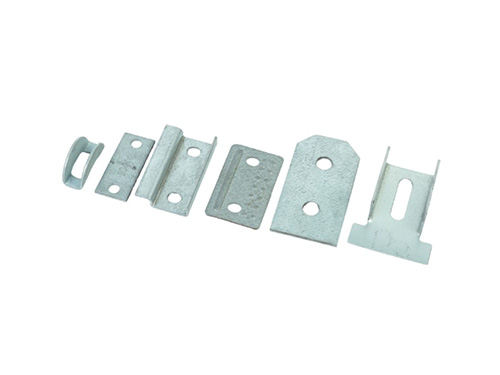

1.1 Hinges&Rotating Joints

Design Features:Core components for rigid-flexible folding transitions,featuring adjustable damping and precise positioning.For foldable solar panels,hinges adopt a dual-axis rotating structure to support multi-angle deployment.

Materials:High-strength engineering plastics(PA6+GF30,POM)for lightweight designs;stainless steel 304/316 for corrosion resistance in outdoor applications.Premium models use titanium alloy to reduce weight by 30%vs.steel.

Performance Metrics:Torque range 0.5–5N·m;folding durability≥50,000 cycles;water/dust resistance≥IP67.

Applications:Foldable solar charging panels,electric folding bikes(e.g.,Ossby Curve Electric’s frame folding joints).

Manufacturing Processes:Injection molding(plastic hinges),precision machining(metal joints),laser welding(assembly),and surface treatment(anodizing,PVD coating).

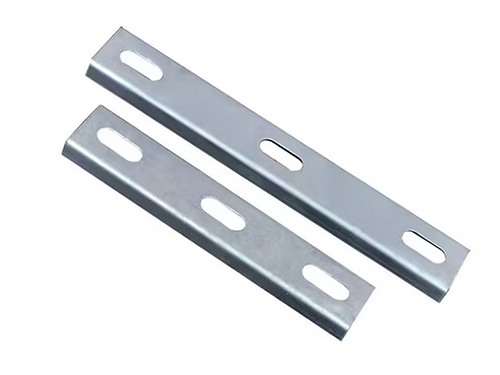

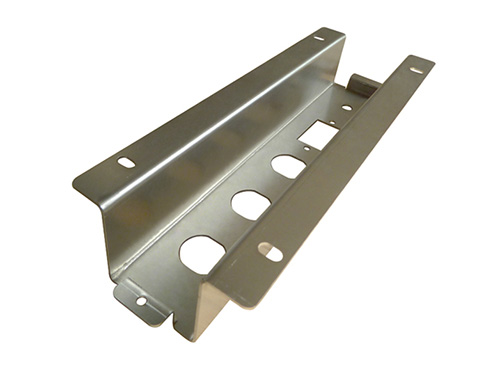

1.2 Flexible Support Frames

Design Features:Integrate with battery housings to provide structural support while enabling folding.For soft-pack batteries,frames adopt a segmented design with foldable connecting strips.

Materials:Glass fiber-reinforced TPU(flexural modulus 150–300MPa),carbon fiber fabric(areal density 150–300g/m²),or aluminum alloy sheets(thickness 0.2–0.5mm)for rigid-flexible hybrid structures.

Key Innovations:Island-bridge structure(rigid"islands"for cell mounting,flexible"bridges"for folding)to balance support and flexibility.

Applications:Flexible wearable batteries,foldable smartphone batteries,portable power stations.