-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

A bracket is a fundamental structural component designed to support, fix, or connect equipment, materials, or architectural elements—transferring loads to stable structures (e.g., walls, beams, or frames) while ensuring positional stability. With diverse designs tailored to specific use cases, brackets are widely used across construction, manufacturing, furniture, and renewable energy industries. Below is a comprehensive overview, ideal for product catalogs, technical manuals, or B2B sales materials:

1. Core Functions & Key Roles

Load Bearing: Distribute vertical/horizontal loads (e.g., weight of equipment, materials, or structural components) to underlying structures, preventing deformation or collapse.

Fixation & Positioning: Secure objects in place (e.g., shelves, pipes, or solar panels) to avoid displacement caused by vibration, wind, or external forces.

Connection & Reinforcement: Bridge gaps between components, reinforcing joints (e.g., corner brackets for furniture) or enabling modular assembly.

Space Optimization: Support objects in suspended or elevated positions (e.g., wall-mounted brackets for shelves), maximizing floor/vertical space utilization.

2. Common Types & Classification

2.1 By Application Field

Construction Brackets:

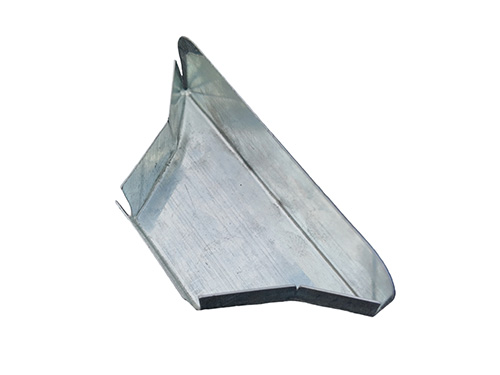

Roof Brackets (e.g., color steel tile brackets): Fix roofing materials to purlins, ensuring wind resistance and waterproofing.

Wall Brackets: Support exterior cladding, windows, or air conditioning units, with load-bearing capacities of 50–500kg.

Scaffolding Brackets: Extend scaffolding platforms for high-altitude construction, featuring anti-slip and lockable designs.

Industrial Brackets:

Equipment Brackets: Mount motors, pumps, or control panels in factories, with corrosion-resistant and vibration-damping features.

Pipe/Cable Brackets: Organize and support pipelines (water, gas, or electrical cables) in industrial facilities, ensuring neat routing and load distribution.

Furniture Brackets:

Shelf Brackets: Support bookshelves, cabinets, or floating shelves (adjustable or fixed designs, load capacity 5–30kg per bracket).

Corner Brackets: Reinforce furniture joints (e.g., table corners, cabinet edges) to prevent loosening.

Renewable Energy Brackets:

Solar Panel Brackets: Secure PV modules to rooftops or ground mounts, optimized for sun exposure and weather resistance.

Wind Turbine Brackets: Reinforce turbine components, with high-strength designs to withstand extreme wind loads.

2.2 By Material

Steel Brackets: Hot-dip galvanized carbon steel (Q235/1018) or stainless steel (304/316) for high strength and corrosion resistance. Ideal for construction, industrial, and outdoor applications (service life 15–30 years).

Aluminum Alloy Brackets: Lightweight, rust-resistant, and easy to machine. Suitable for lightweight equipment, solar panels, or furniture (load capacity 10–200kg).

Plastic Brackets: Cost-effective, non-conductive, and corrosion-proof. Used for indoor applications (e.g., cable management, furniture accessories) with low load requirements.

Wooden Brackets: Aesthetic, eco-friendly, and suitable for decorative or lightweight support (e.g., shelf brackets in residential settings).

2.3 By Structural Design

L-Shaped Brackets: Simple, versatile design for corner support or wall mounting (e.g., shelf brackets, equipment mounts).

U-Shaped Brackets: Wrap around objects for secure fixation (e.g., pipe brackets, solar panel clamps).

Angle Brackets: Reinforce right-angle joints (e.g., furniture corners, construction beams) with triangular or rectangular profiles.

Adjustable Brackets: Feature sliding or telescopic structures to adapt to different sizes or angles (e.g., adjustable shelf brackets, tiltable solar mounts).

3. Key Specifications & Quality Standards

Load Capacity: Ranges from 1kg (lightweight furniture brackets) to 5000kg+ (heavy-duty industrial/construction brackets), tested to meet ISO 898 or GB/T 3098 standards.

Material Thickness: 1–10mm (steel brackets) or 2–8mm (aluminum brackets), depending on load requirements.

Corrosion Protection: Hot-dip galvanized (zinc coating ≥85μm), electrostatic spraying, or stainless steel construction for outdoor/harsh environments.

Dimensional Tolerance: ±0.5mm for precision applications (e.g., industrial equipment mounts), ensuring compatibility with connected components.

4. Installation & Selection Considerations

4.1 Installation Tips

Ensure the mounting surface (wall, beam) is stable and load-bearing; reinforce weak surfaces with backing plates if needed.

Use compatible fasteners (screws, bolts, or anchors) based on the bracket material and mounting surface (e.g., expansion bolts for concrete walls).

Follow recommended spacing between brackets (e.g., 600–1200mm for shelf brackets) to distribute loads evenly.

4.2 Selection Guidelines

Load Requirements: Match the bracket’s load capacity to the intended use (e.g., heavy-duty steel brackets for industrial equipment).

Environmental Conditions: Choose corrosion-resistant materials (stainless steel, aluminum) for coastal, humid, or chemical environments.

Compatibility: Ensure the bracket’s size, shape, and mounting holes align with the supported object and installation surface.

Quality Certification: Select products compliant with industry standards (e.g., ISO 9001, CE) to guarantee durability and safety.

Brackets are indispensable across industries, combining functionality, durability, and versatility to meet diverse support needs. By selecting the right type, material, and specifications, you can ensure structural stability, extend the service life of connected components, and optimize space utilization.