-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

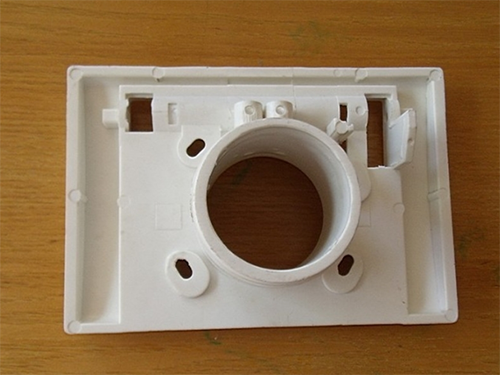

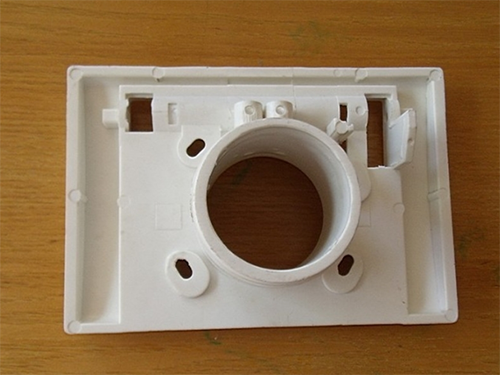

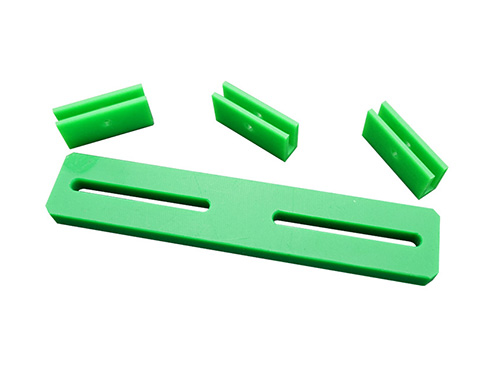

Injection molded parts are high-precision components produced via injection molding—a manufacturing process that melts thermoplastic or thermosetting polymers,injects the molten material into a custom-designed mold cavity,and allows it to cool and solidify into the desired shape.Renowned for its efficiency,repeatability,and ability to produce complex geometries with tight tolerances,injection molding is the most widely used polymer processing technology,serving industries such as automotive,consumer electronics,medical devices,packaging,and household goods.From smartphone casings and automotive interior trim to surgical instruments and battery components,injection molded parts leverage diverse polymer materials(plastics,elastomers,composites)to deliver lightweight,durable,and cost-effective solutions.This document comprehensively covers injection molded part classifications,material selection,mold design,manufacturing workflows,quality control,and industry applications,integrating the latest technical innovations and standard specifications.

I.Core Definitions&Functional Roles

1.What Are Injection Molded Parts?

Injection molded parts are polymer-based components formed by the injection molding process,with core functional objectives tailored to application requirements:

Complex Geometry Replication:Produce parts with intricate internal/external features(ribs,bosses,undercuts,thin walls)that are difficult to achieve via other manufacturing methods.

High-Volume Production:Enable mass production of consistent,repeatable parts(10,000–10,000,000+units/year)with minimal variation.

Material Versatility:Accommodate thermoplastics,thermosets,elastomers,and polymer composites,tailoring properties(strength,flexibility,heat resistance,biocompatibility)to end-use needs.

Lightweight&Cost-Effective:Reduce weight by 30–70%compared to metal alternatives;lower production costs via automated processes and minimal post-processing.

Functional Integration:Combine multiple components into a single part(e.g.,integrated fasteners,gaskets)to reduce assembly time and improve reliability.

2.Key Performance Benchmarks

Injection molded parts must meet rigorous performance criteria to ensure quality,durability,and compatibility:

Dimensional Precision:Dimensional tolerance±0.02mm(precision parts)or±0.1mm(general-purpose parts);surface roughness Ra≤0.8μm(polished molds)or Ra≤6.3μm(standard molds).

Mechanical Properties:Tensile strength≥20MPa(general plastics)or≥100MPa(reinforced composites);elongation≥5%(thermoplastics);flexural modulus≥1GPa(rigid parts).

Environmental Resistance:Heat resistance up to 250℃(high-performance polymers);chemical resistance to oils,solvents,and disinfectants(automotive/medical parts);UV resistance≥1000 hours(outdoor parts).

Durability:Fatigue life≥10⁶cycles(dynamic components);impact strength≥20kJ/m²(Izod test,ASTM D256)for tough applications.

Safety Compliance:Meet industry-specific standards(e.g.,FDA 21 CFR Part 177 for food-contact parts;ISO 10993 for medical devices;UL 94 for flame retardancy).