-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

Battery structural components serve as the critical mechanical framework for battery packs, integrating functions of mechanical support, safety protection, thermal management, electrical insulation, and lightweight optimization. With the rapid development of electric vehicles (EVs) and energy storage systems (ESS), these components are evolving toward integration, lightweighting, and intelligence—driven by technologies such as cell-to-pack (CTP), cell-to-chassis (CTC), and advanced composite materials. This document comprehensively covers core classifications, material innovations, manufacturing processes, performance standards, and cutting-edge trends, incorporating the latest industry practices (e.g., 4680 battery structural solutions) and enterprise cases.

I. Core Classification & Functional Evolution

1. Traditional Key Components (Optimized with Latest Data)

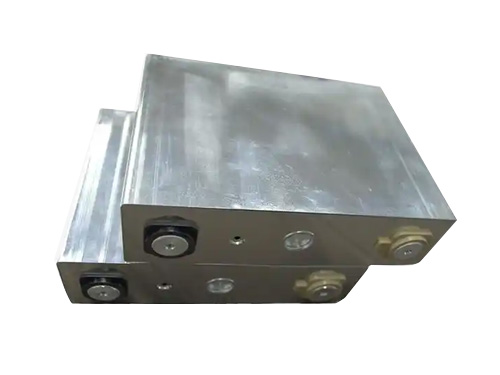

1.1 Battery Pack Housing

Material Upgrade:

Aluminum Alloy (6061/6063): Dominates mid-to-high-end EVs, with integrated die-casting technology (e.g., NIO ET5's 6000T die-cast housing) reducing welds by 80% and weight by 10–15% .

Continuous Fiber-Reinforced Thermoplastics (CFRTP): Developed by Fraunhofer LBF, the 3D sandwich-structured housing achieves 40% weight reduction vs. aluminum, with a production cycle of only 2 minutes via in-situ CFRTP sandwich process .

Hybrid Solutions: BYD's SMC composite upper cover + high-strength aluminum lower tray balances cost and performance; CATL's basalt fiber-reinforced aluminum alloy housing optimizes volume by 26% .

Sealing Performance: Meets IP67/IP6K9K standards, with helium leakage rate ≤1×10⁻⁹Pa·m³/s for 4680 battery steel cases .

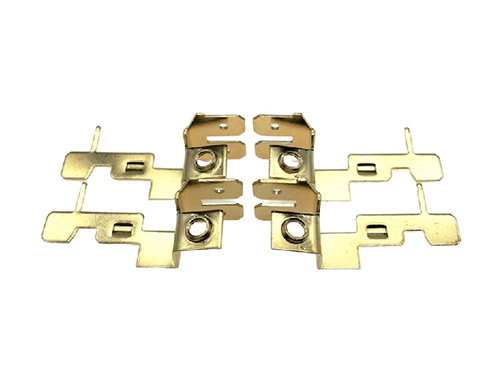

1.2 Cell/Module Holders & Trays

4680 Battery-Specific Design:

Nickel-plated steel cases: Adopt high-quality alloy steel with precision stamping and drawing processes, wall thickness uniformity controlled within ±0.01mm, nickel plating thickness 5–10μm (7±1μm for 3JM products), salt spray resistance ≥1000 hours .

Caps: Integrate cover plates, poles, injection holes, flip sheets, and explosion-proof discs. 3JM's caps feature pole conductivity ≥60%IACS and explosion-proof disc activation pressure 1.5–2.0MPa .

Modular Optimization: For CTP/CTC systems, injection-molded PP/PA6+GF30 holders with precision positioning (tolerance ±0.05mm) replace traditional modules, reducing parts count by 20% .

1.3 Cooling System Structural Components

Integrated Thermal-Structural Design: BYD's steam direct-contact cooling pipes replace liquid cooling mechanisms, reducing auxiliary system weight by 13.7% with temperature uniformity standard deviation <0.9℃ .

Cooling Plates: Stamped aluminum 3003/5052 plates with microchannels (width 3–5mm) for 4680 battery packs, heat transfer capacity ≥100W/m·K .

1.4 Bracing & Reinforcement Components

Energy Absorption Innovation: Foam aluminum sandwich structures (0.5mm CFRP + 3mm foam aluminum) enhance bending stiffness by 30% ; GAC's 3D mesh aluminum-based brackets improve load distribution efficiency by 45% .

Crashworthiness: High-strength steel (HSS/AHSS) crash rails with yield strength ≥780MPa, absorbing ≥20kJ impact energy for EV packs .

1.5 Insulation & Sealing Components

High-Performance Materials: King Young New Materials' polyimide insulation sheets offer breakdown voltage ≥10kV/mm; EPDM gaskets withstand -40℃ to 150℃ .

Flame Retardancy: SMC composite components meet UL94 V-0 standard, integrating flame resistance into structural design .

2. Emerging Integrated Components (CTC/CTP Era)

2.1 Cell-to-Pack (CTP) Structural Systems

Key Features: Cancel traditional modules, directly integrate cells into the housing (e.g., Tesla 4680 CTC), reducing cost by 10–20% and improving energy density by 15–20% .

Structural Requirements: CATL's CTP5.0 platform increases cell load-bearing capacity from 78% to 90%, requiring tray bending stiffness ≥1.2×10⁵ N·m²/m .

2.2 Cell-to-Chassis (CTC) Integration

Housing-Chassis Integration: Tesla's 4680 battery pack integrates with the vehicle chassis, using CFRP composite materials to reduce weight by 30% while increasing rigidity by 50% .

Precision Requirements: Cell positioning tolerance ±0.05mm, requiring advanced robotic assembly and laser alignment .