-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

Air conditioning parts are specialized components that constitute residential,commercial,and industrial HVAC(Heating,Ventilation,and Air Conditioning)systems,working synergistically to regulate temperature,humidity,and air quality.These parts range from precision mechanical components to thermal and electrical elements,each engineered to ensure energy efficiency,reliability,and optimal performance.Leveraging manufacturing processes like stamping,sheet metal forming,and precision machining—many of which align with previously detailed stamping technologies—air conditioning parts are produced to meet strict industry standards for durability and functionality.

I.Core Classification of Air Conditioning Parts

Air conditioning systems comprise three primary subsystems(compression,condensation,evaporation)plus auxiliary components,leading to the following key classifications:

1.Compressor&Refrigeration Cycle Parts

Compressor:The"heart"of the system,compressing low-pressure refrigerant vapor into high-pressure gas.Key types include scroll,rotary,and reciprocating compressors,with components like stamped steel valve plates,aluminum alloy pistons,and precision-machined crankshafts.

Condenser Coils:Heat-exchange components(typically copper tubes with aluminum fins)that condense refrigerant vapor into liquid.Fins are often produced via stamping and lamination processes for uniform heat transfer.

Evaporator Coils:Facilitate refrigerant evaporation to absorb indoor heat,constructed with copper/aluminum tubes and stamped aluminum fins(corrosion-resistant coatings for durability).

Expansion Valve/Metering Device:Regulates refrigerant flow,featuring precision-machined valve cores and stamped brass bodies for pressure control.

2.Air Handling&Distribution Parts

Blower Wheels/Fans:Generate airflow,with stamped steel or plastic blades(balanced for low noise).Centrifugal blower wheels use sheet metal stamping and welding for structural integrity.

Air Filters:Capture dust and particles—frames are often stamped sheet metal(galvanized steel)or plastic,with filter media(HEPA,activated carbon)for air purification.

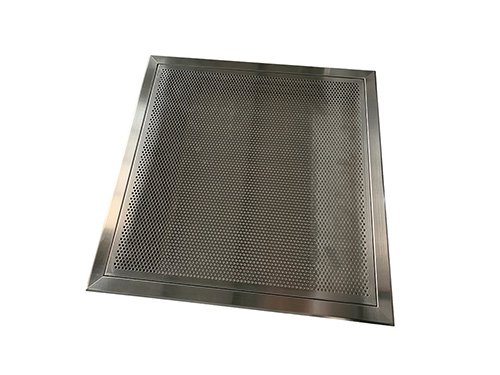

Ductwork&Vent Covers:Sheet metal components(galvanized steel,aluminum)produced via bending,stamping,and welding.Vent covers feature stamped perforations for airflow regulation.

Damper Plates:Control air flow direction,made from stamped steel or aluminum with precision hinges(stamped via progressive die processes for consistency).

3.Structural&Mounting Components

Chassis&Brackets:Support internal components,fabricated from stamped sheet metal(Q235 carbon steel,galvanized steel)for high strength-to-weight ratio.Many use stamping processes like bending,punching,and embossing—aligning with the forming stamping parts detailed earlier.

Housings&Casings:External enclosures(sheet metal or plastic)for indoor/outdoor units.Sheet metal housings undergo stamping,folding,and powder coating for corrosion resistance.

Vibration Dampers:Rubber or spring components mounted on stamped steel brackets to reduce noise and vibration from compressors and fans.

4.Electrical&Control Parts

Motor Assemblies:Drive compressors and fans,with stamped steel motor frames,copper windings,and precision bearings.Stamped terminal blocks ensure electrical connectivity.

Capacitors:Store electrical energy,featuring stamped aluminum casings and brass terminals(stamped for secure contact).

Thermostats&Sensors:Temperature/humidity detection components,with stamped metal housings(stainless steel for corrosion resistance)and electronic sensing elements.

Circuit Boards&Connectors:Electrical control centers,with stamped copper terminals and sheet metal heat sinks(produced via stamping and forming processes).

II.Key Materials for Air Conditioning Parts

Materials are selected based on functionality(heat transfer,structural support,electrical conductivity)and environmental conditions(moisture,temperature fluctuations):

Metals&Alloys:

Copper/Brass:High thermal/electrical conductivity—used in coils,valves,and connectors.

Aluminum/Aluminum Alloys(5052,6061):Lightweight,good heat transfer—ideal for fins,blower wheels,and sheet metal housings.

Galvanized Steel/Q235 Carbon Steel:Corrosion-resistant,high strength—for chassis,brackets,ductwork(stamped and welded per stamping processing standards).

Stainless Steel(304):Hygienic,corrosion-resistant—for commercial HVAC components(e.g.,hospital air handlers).

Plastics&Polymers:

ABS,PP,and Nylon:Lightweight,cost-effective—for fan blades,filter frames,and decorative covers.

Rubber/EPDM:Vibration dampening,sealing—for gaskets and O-rings.

Composite Materials:

Fiberglass-Reinforced Plastic(FRP):Corrosion-resistant,insulation—for ductwork in harsh environments.

III.Manufacturing Processes for Air Conditioning Parts

Many air conditioning parts leverage manufacturing technologies detailed in previous stamping and sheet metal documents:

Stamping&Sheet Metal Forming:Stamped fins,brackets,chassis,valve plates,and terminal blocks use progressive die stamping,bending,and punching(tolerance±0.05–±0.1mm for precision fit).

Machining:Precision components like compressor crankshafts,valve cores,and motor shafts undergo CNC turning/milling.

Welding&Assembly:Sheet metal ductwork,chassis,and coil assemblies use spot welding,MIG welding,or brazing(for copper tubes).

Surface Treatment:Powder coating(steel chassis),anodizing(aluminum fins),and galvanization(ductwork)enhance corrosion resistance.

Thermal Processing:Heat treatment for compressor components(e.g.,crankshafts)to improve strength and wear resistance.

IV.Core Performance Requirements&Quality Standards

Energy Efficiency:Components like coils(stamped fins with optimized spacing)and compressors(precision-machined parts)must meet SEER(Seasonal Energy Efficiency Ratio)standards(≥14 SEER for residential units).

Durability:Corrosion resistance(salt spray tests per ASTM B117 for coastal applications),vibration resistance(10–50Hz frequency tests),and temperature tolerance(-40°C to 60°C for outdoor parts).

Noise Reduction:Balanced stamped fan blades,vibration-damping brackets,and precision bearings ensure low noise levels(≤45dB for residential indoor units).

Industry Standards:Compliance with ASHRAE(American Society of Heating,Refrigerating and Air-Conditioning Engineers),ISO 9001,and safety standards(UL,CE)for electrical components.

V.Typical Applications&Market Segments

Residential HVAC:Split-system air conditioners,window units—parts include small scroll compressors,stamped aluminum fins,and plastic blower wheels.

Commercial HVAC:Rooftop units,chillers,air handlers—components like large-scale coil assemblies,sheet metal ductwork,and industrial-grade compressors.

Industrial HVAC:Process cooling systems,cleanroom air conditioning—corrosion-resistant parts(stainless steel,FRP)and high-capacity heat exchangers.

Automotive HVAC:In-vehicle air conditioners—compact compressors,stamped aluminum evaporators,and blower motors(lightweight materials for fuel efficiency).

VI.Key Considerations for Selection&Maintenance

Compatibility:Ensure parts match system specifications(e.g.,compressor type,coil size,voltage rating).

Material Suitability:Choose corrosion-resistant materials for humid/coastal environments(e.g.,galvanized steel brackets,304 stainless steel coils).

Quality Certification:Select parts from suppliers with ISO 9001 and HVAC-specific certifications(e.g.,AHRI—Air-Conditioning,Heating,and Refrigeration Institute).

Maintenance Accessibility:Opt for parts with standardized designs(e.g.,stamped sheet metal housings with removable panels)for easy servicing.

Air conditioning parts are the backbone of efficient climate control,integrating precision manufacturing processes like stamping and sheet metal forming to deliver reliability and performance.As the HVAC industry shifts toward energy efficiency and sustainability,parts are evolving to use lightweight materials,optimized stamping designs,and advanced thermal management—ensuring systems meet global environmental standards while providing consistent comfort.Whether for residential cooling or industrial process control,high-quality air conditioning parts are critical to minimizing energy consumption and extending system lifespan.