-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

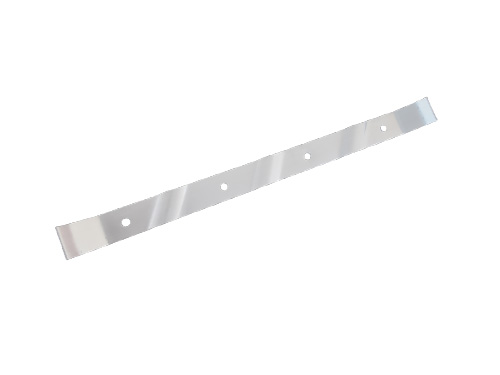

Color steel tile pressure strips(also known as roof clamping strips or tile fixing bars)are essential structural accessories designed to secure color steel tiles,seal gaps,and enhance the stability of roofing systems.Widely used in industrial workshops,warehouses,prefabricated buildings,and commercial facilities,these strips work with brackets,screws,and sealing materials to prevent tile displacement caused by wind,thermal expansion,or external loads—while reinforcing waterproof performance.Below is a detailed 500-word introduction,ideal for product manuals or B2B sales materials:

1.Core Functions&Key Roles

Secure Fixation:Clamp color steel tiles firmly to purlins or brackets,distributing pressure evenly across the tile surface to avoid local deformation.A single pressure strip typically secures 1–2 tile edges,with a wind resistance capacity of up to 35m/s,preventing tile lifting in extreme weather.

Waterproof Sealing:When paired with EPDM gaskets or butyl rubber strips,the strips seal gaps between tiles and fixing points,eliminating rainwater infiltration paths.This avoids leakage issues caused by direct screw drilling into tiles.

Stress Dissipation:Accommodate slight thermal expansion and contraction of color steel tiles(±5mm/m)to reduce structural stress,preventing tile cracking or joint separation over time.

Structural Reinforcement:Enhance the overall rigidity of the roofing system,supporting maintenance personnel and snow loads(typical load-bearing capacity:0.8–2.0kN/m).

2.Common Types&Material Specifications

By Material:

Galvanized Steel Strips:Hot-dip galvanized Q235 steel,corrosion-resistant,cost-effective,and suitable for most indoor/outdoor environments.Thickness ranges from 1.0–2.0mm,with a zinc coating thickness≥85μm(compliant with GB/T 13912-2022),service life 15–20 years.

Stainless Steel Strips:304/316 stainless steel,ideal for coastal areas or chemical plants.Resistant to salt spray and chemical erosion,with a service life of 25–30 years.

Aluminum Alloy Strips:Lightweight(1/3 the density of steel),flexible,and corrosion-resistant,suitable for lightweight roofing systems or projects requiring easy installation.

By Structure:

U-Shaped Strips:Used for corrugated or trapezoidal tiles,with a concave design that fits tile profiles tightly.

L-Shaped Strips:Applied at roof edges,eaves,or parapet walls,combining fixation and edge sealing.

Channel Strips:Specialized for standing-seam tiles,featuring a groove design to accommodate tile seams and sliding mechanisms for thermal expansion.

3.Key Design Features&Quality Standards

Profile Compatibility:Pre-formed to match common color steel tile profiles(e.g.,760/820mm trapezoidal tiles,430mm standing-seam tiles),ensuring a snug fit without gaps.

Sealing Integration:Equipped with pre-installed EPDM foam or butyl rubber strips,eliminating the need for secondary sealing and improving construction efficiency.

Easy Installation:Pre-drilled holes(spacing 300–500mm)for quick attachment with self-tapping screws or bolts,reducing labor costs.

Quality Compliance:Must meet GB/T 2518-2019(color steel tile standards)and pass wind load,corrosion,and waterproof tests.The surface should be free of burrs,rust,or deformation.

4.Installation&Application Scenarios

Installation Process:

Clean the tile surface and align the pressure strip with the tile edge or joint.

Secure the strip to purlins/brackets using screws,ensuring the sealing gasket is compressed(compression rate:30–50%)for effective waterproofing.

Overlap adjacent strips by 5–10cm and seal joints with silicone sealant for enhanced water resistance.

Typical Applications:

Industrial workshops,logistics warehouses,stadiums,modular houses,and coastal buildings.Suitable for corrugated,trapezoidal,and standing-seam color steel roofs,as well as wall cladding systems.

5.Selection Considerations

Tile Compatibility:Choose strips matching the tile’s profile,thickness,and installation position(eaves,ridges,or mid-span).

Environmental Adaptation:Opt for galvanized steel for general use,stainless steel for coastal/humid areas,and aluminum alloy for lightweight projects.

Sealing Performance:Prioritize strips with integrated high-quality EPDM gaskets to avoid aging-related leakage.

Quality Certification:Select products with ISO 9001 certification and compliance with national building codes.

Color steel tile pressure strips are critical to the long-term stability and waterproof performance of roofing systems.By selecting compatible,high-quality strips and following standard installation procedures,you can ensure the roof’s durability,reduce maintenance costs,and mitigate risks of tile displacement or leakage.