-

E-mail:

18333041899@163.com -

Tel:

86-18333041899

E-mail:

18333041899@163.comTel:

86-18333041899

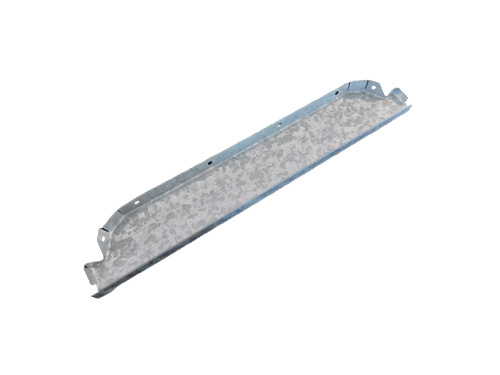

Color steel tile sealing baffles(also called roof edge sealing plates or tile gap baffles)are essential protective accessories for color steel roofing systems.Designed to seal gaps at roof edges,ridges,eaves,and tile joints,they prevent water leakage,wind infiltration,dust accumulation,and pest intrusion—critical for enhancing the roofing system’s durability,waterproof performance,and energy efficiency.Widely used in industrial workshops,warehouses,prefabricated buildings,and commercial facilities,these baffles complement color steel tiles and brackets to form a complete,weathertight roofing structure.Below is a detailed overview(suitable for product manuals,B2B sales materials,or construction guides):

1.Core Functions&Key Roles

Waterproof Sealing:Block rainwater,snowmelt,and condensation from seeping into the roof through gaps(e.g.,between tile edges,at ridge joints,or around chimneys/vent pipes),eliminating leakage risks.

Wind Resistance:Prevent strong winds from lifting color steel tiles or infiltrating the roof cavity,reducing structural stress and heat loss.

Insulation Enhancement:Seal air gaps to minimize heat transfer between the interior and exterior,improving the building’s thermal insulation and energy efficiency(reducing heating/cooling costs by 10–15%).

Protective Barrier:Block dust,leaves,birds,and rodents from entering the roof structure,avoiding damage to insulation materials or corrosion of steel components.

2.Common Types&Structural Designs

2.1 By Installation Position

Ridge Sealing Baffles:Arc-shaped or triangular plates installed at the roof ridge(peak),sealing the gap between two sloped roof sections.Equipped with waterproof gaskets or foam strips to adapt to thermal expansion.

Eave Sealing Baffles:Installed at the lower edge of the roof(eaves),preventing rainwater from dripping along the tile edges and protecting the building’s exterior walls.Often designed with drainage slots to guide water flow.

Tile Joint Sealing Baffles:Thin,flexible plates inserted between adjacent color steel tiles,sealing longitudinal or transverse gaps.Suitable for corrugated,trapezoidal,or standing-seam tiles.

Edge/Cornice Sealing Baffles:Used at roof corners,parapet walls,or where the roof meets vertical structures(e.g.,walls,chimneys),forming a tight seal at irregular joints.

2.2 By Material&Structure

Galvanized Steel Baffles:Hot-dip galvanized or electro-galvanized carbon steel(Q235),corrosion-resistant,high-strength,and cost-effective.Thickness ranges from 0.6mm to 1.2mm,with a service life of 15–20 years.

Stainless Steel Baffles:304/316 stainless steel,excellent corrosion resistance for coastal areas,chemical plants,or humid environments.Resistant to salt spray and chemical erosion,service life 25–30 years.

Aluminum Alloy Baffles:Lightweight,flexible,and corrosion-resistant,ideal for lightweight roofing systems or projects requiring easy bending/adaptation to irregular shapes.

Composite Baffles:Steel core with PVC or EPDM rubber layers,combining structural strength with enhanced waterproofing.Suitable for high-humidity or heavy-rain regions.

2.3 Key Design Features

Pre-formed Profiles:Customized to match color steel tile profiles(corrugated,trapezoidal,standing-seam)for a tight fit,avoiding gaps.

Waterproof Sealing Layers:Integrated EPDM foam strips,silicone gaskets,or butyl rubber tapes at contact points,ensuring long-term waterproofing without secondary sealing.

Thermal Expansion Adaptation:Flexible or segmented designs to accommodate slight movement of color steel tiles due to temperature changes,preventing cracking or detachment.

Easy Installation:Pre-drilled holes or clamp-style structures for quick attachment to purlins,brackets,or tiles,reducing construction time.

3.Key Specifications&Quality Standards

Dimensions:Length 1–3m(customizable),width 100–300mm(adjusted based on gap size),thickness 0.6–1.2mm(depending on material and load requirements).

Corrosion Protection:Galvanized steel baffles require zinc coating thickness≥85μm(compliant with GB/T 13912-2022);stainless steel baffles meet ASTM A240 standards.

Waterproof Performance:Must pass 24-hour water immersion tests or rain simulation tests without leakage(compliant with GB/T 2518-2019).

Wind Load Resistance:Withstand wind speeds up to 25–35m/s(adjusted for regional wind codes)without deformation or detachment.

4.Installation&Application Scenarios

4.1 Installation Process

Clean the installation area(roof edges,joints)to remove dust,debris,or rust,ensuring a smooth surface.

Cut the baffle to the required length(allow 5–10cm overlap for joint sealing if using multiple pieces).

Position the baffle at the target gap,aligning with the tile profile.Secure it using self-tapping screws,rivets,or clamps(spacing 300–500mm)to purlins or brackets.

Press the integrated sealing strip firmly against the tile or roof structure to ensure full contact;apply additional silicone sealant at joints for enhanced waterproofing(optional for heavy-rain regions).

4.2 Typical Applications

Industrial buildings:Workshops,warehouses,logistics centers,and manufacturing facilities(large-span roofing systems).

Commercial facilities:Shopping malls,exhibition halls,and office buildings.

Prefabricated buildings:Modular houses,temporary offices,and disaster relief shelters.

Special environments:Coastal areas(stainless steel baffles),chemical plants(corrosion-resistant materials),and cold regions(snowmelt waterproofing).

5.Selection&Purchase Considerations

Tile Compatibility:Choose baffles matching the color steel tile’s profile(corrugated,trapezoidal,standing-seam)to ensure a tight fit.

Environmental Adaptation:Opt for galvanized steel for general use,stainless steel for coastal/humid/chemical environments,and aluminum alloy for lightweight projects.

Waterproof Requirements:Prioritize baffles with integrated EPDM or butyl rubber sealing layers for long-term waterproofing;avoid low-quality materials prone to aging.

Quality Certification:Select products compliant with national standards(GB/T 2518-2019,GB/T 13912-2022)and ISO 9001 quality management system.

Installation Ease:Prefer baffles with pre-drilled holes or clamp-style designs to simplify construction and reduce labor costs.

Color steel tile sealing baffles are a small but critical investment in roofing system durability.By selecting high-quality,compatible baffles and following standard installation procedures,you can effectively prevent water leakage,wind infiltration,and structural damage,extending the roof’s service life and reducing maintenance costs.